Industrial Fluid Handling Systems. Engineered to Eliminate Failure.

Stop guessing on chemical compatibility. Get direct access to James Riggins for spec-ready Water Treatment, Chemical Feed, and Process Control systems.

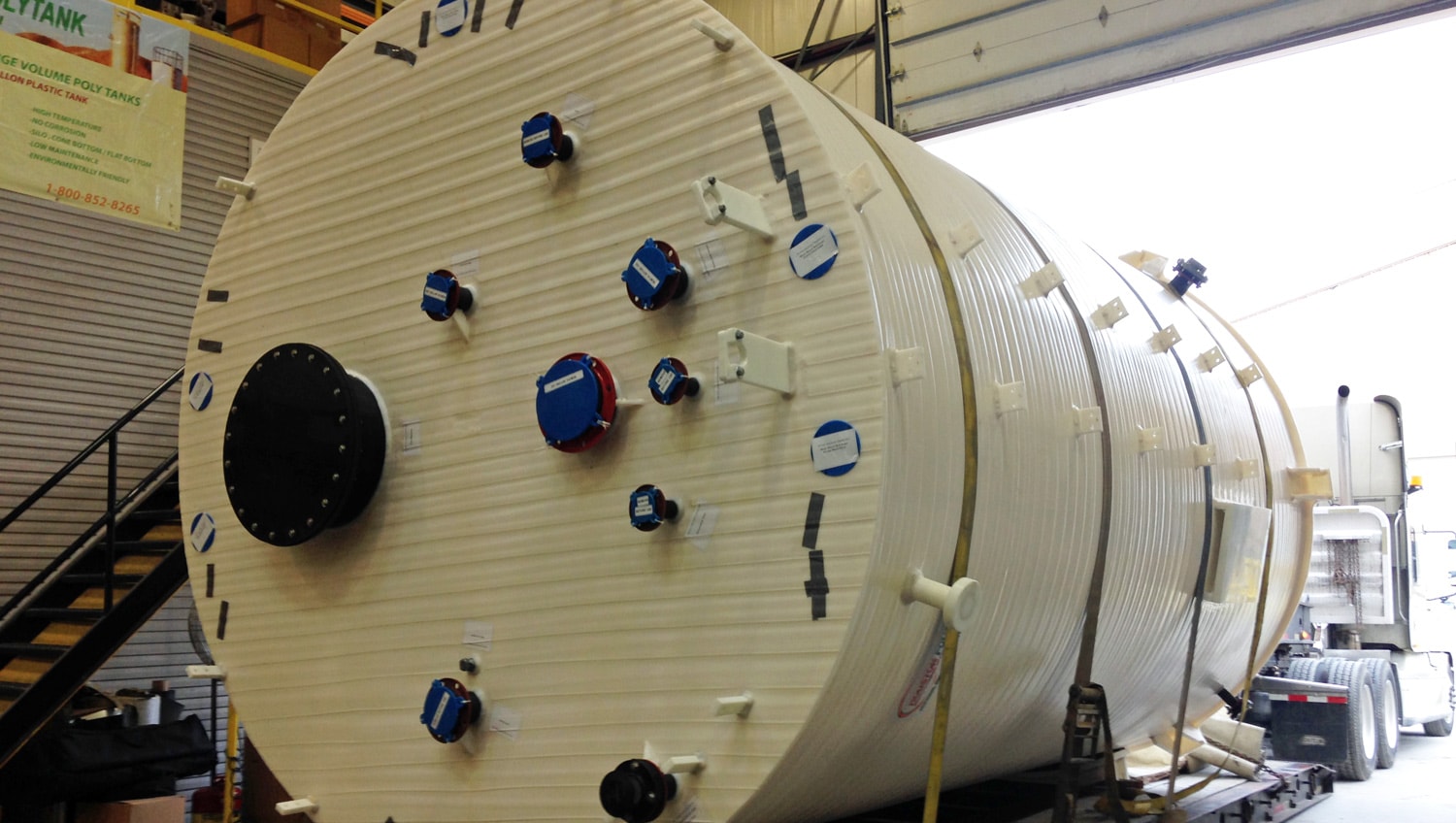

The James-Spec System Architecture

Built for engineers and operators who don’t have time for “maybe.” These are the core systems LibertyCES specs to protect uptime.

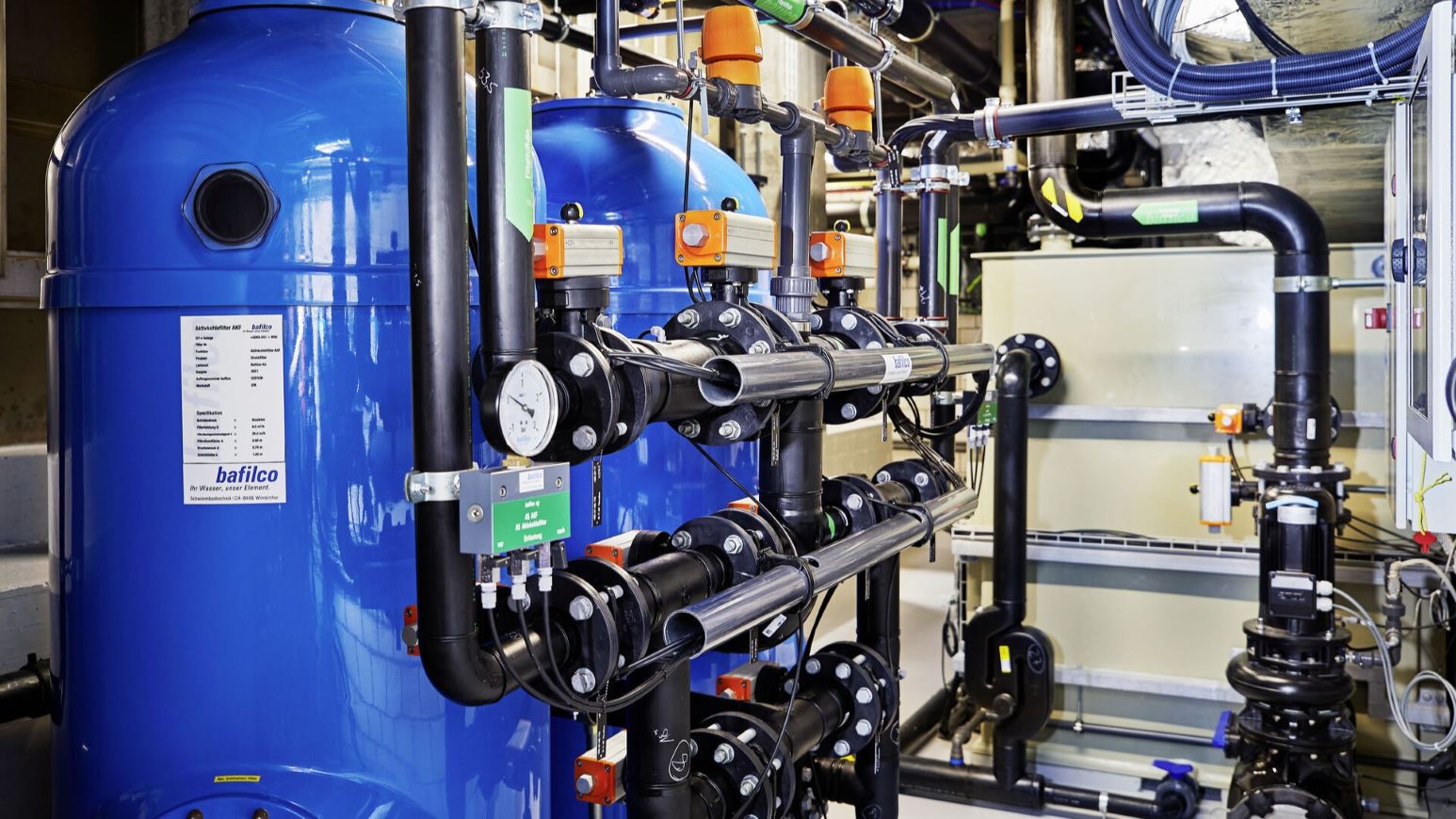

Precision pH Control for Industrial Wastewater

Operators were flying blind without feedback. We designed a closed-loop system so the plant never risks overshooting again.

The Result: Smart electric dosing eliminated overshooting, cut chemical waste by 24%, and secured EPA compliance.

The Rapid Spec Workflow

Engineers move fast when the inputs are clear. This keeps communication tight and the outcome verified.

The Input

Send us a photo, a datasheet, or just a description of the problem.

The Review

James reviews the hydraulics, chemistry, and duty cycle.

The Solved

You get a verified spec or a system quote that works.

Answers Plant Teams Search When Things Start Failing

Real operator questions—answered with a systems mindset.